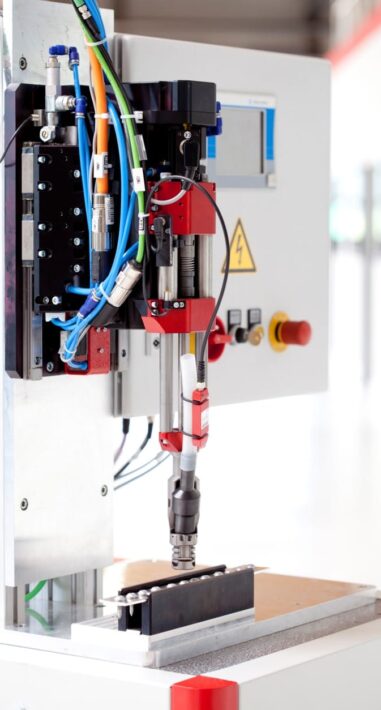

Automatic Screwdriver for flowdrilling screws with automatic feeding (FSF)

Our automatic screwdriver for fitting flow drilling screws has been specially developed for use in the automotive industry. Different materials with thicknesses of up to 5 mm each can be connected to each other. The system can be used stationary or on robots. The drive for the axial movement is situated directly above the screwing tool. The force is therefore initiated centrally over the screw. This means that only very small masses are moved, leverage effects are eliminated. When feeding the screws, the customer can choose between direct feed and magazine loaded feed with automatic or manual filling. In all variants, the screw is always fed forwards with the screw head and only turned briefly in front of the feeding head in order to preserve the screw tips. The controller monitors and documents all screw parameters

Key Advantages

- Fully monitored system with monitoring and documentation of all screw parameters: Torque, rotational angle, screw-in depth, force, contact pressure

- Immediate identification and reporting of any incorrect assemblies

- Screw parameters can be individually parametrized per screw location

- Compact design for hard-to-access screw locations

- Fast bit change without tools

- Feed head can be removed without auxiliary tools

- Feed arm can be changed without auxiliary tools

- Very low moving masses

- Automatic feeding of the screws

- Magazine on the automatic screwdriver with separate filling station

- Gentle feeding principle

- Compact working radius of clamping surface to the screw axis, beneficial robot lever arm

- Can be used as a robot solution in any position