Our History

Dixon Automatic Tool, Inc. has been serving manufacturers and machine builders for over 74 years.

Dixon Research, Inc.

May 1, 2021was founded in March 1946 by Paul H. Dixon.

The Company started as an independent engineering firm located in Rockford, Illinois. The Company’s prime customers were the U.S Government military arsenals. Primary engineering projects were to design and develop rapid firing capabilities for several automatic weapons. The design plans, and fabrication achievements were also to reduce the over-all weight of several weapons for military aircraft. We also improved upon many other automatic firing weapons, such as the anti-tank bazooka rocket launcher, and the rapid-fire Vulcan weapon.

The Company started as an independent engineering firm located in Rockford, Illinois. The Company’s prime customers were the U.S Government military arsenals. Primary engineering projects were to design and develop rapid firing capabilities for several automatic weapons. The design plans, and fabrication achievements were also to reduce the over-all weight of several weapons for military aircraft. We also improved upon many other automatic firing weapons, such as the anti-tank bazooka rocket launcher, and the rapid-fire Vulcan weapon.

The Company continued working on Government projects throughout the 1950’s.

May 2, 2021Origonal Location on Madison Street, Rockford, IL

Dixon Research moved from our facility on Madison Street to a new building at 2300 23rd Ave. in Rockford. Over the next five years, we enlarged the new building three times. In 1952 we re-incorporated the Company name to Dixon Automatic Tool, Inc.

Special Assemblies

May 4, 2021The Company designed and built special assembly machines for a number of companies that were producing phones, communications, furniture, pianos, special fasteners, hardware, clocks, medical devices, and many other products requiring automated assembly machines.

Click Images to Enlarge

In the 1960’s

May 5, 2021

The Company added 5,000 square feet to the original factory’s structure. As we expanded our special machine sales, we recognized a number of part placement designs that could be redesigned and marketed as standard products. Products such as auto-fed screwdrivers, part placing units, and part feeding systems with fastener sensing, part conveyer tracks, and other devices.

Click Images to Enlarge

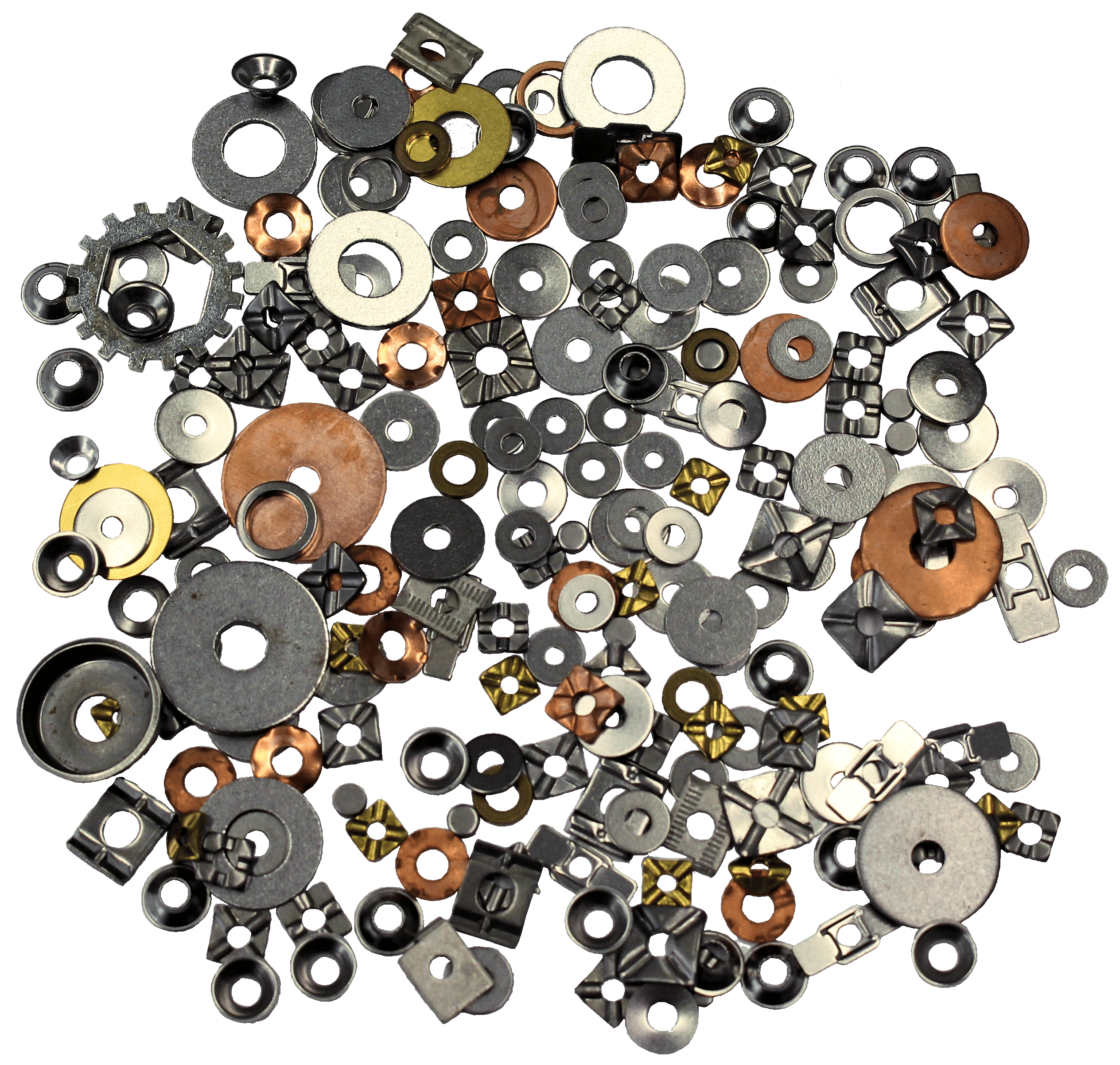

Dixon Components, Inc.

May 5, 2021Founded as a Wholly Owned Subsidiary in 1966.

The Components Division was an out growth of Dixon’s early years with military contracts to design and fabricate preproduction runs of catridge links for munitions.

Dixon Components division soon fulfilled the growing need by the local fastener manufacturers to purchase fabrication washers and special stampings. The Component Division’s major goal was always to meet the customer’s quality standards and delivery requirements. The Components Divison was highly successful in meeting the needs of their customers. ITW Illinois Tool Works purchased the Division in May 1993.

DC Products DC Products2316 23rd Ave, Rockford IL |

Basic Stampings & Wire Clamps Basic Stampings & Wire Clamps |

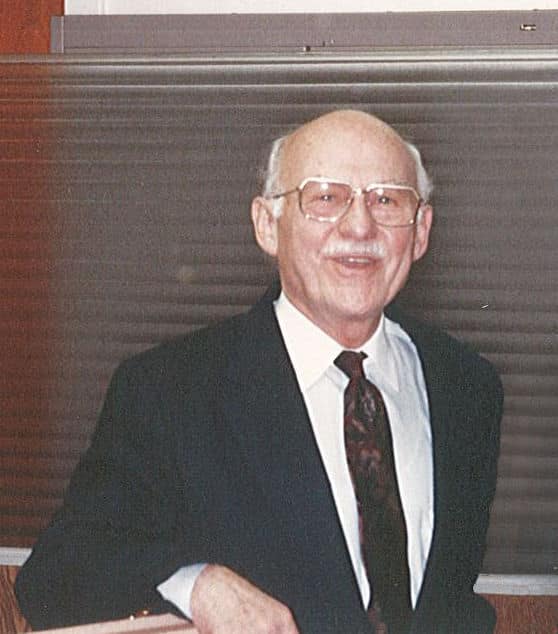

Ernst L. Collin

President Dixon Components Inc.

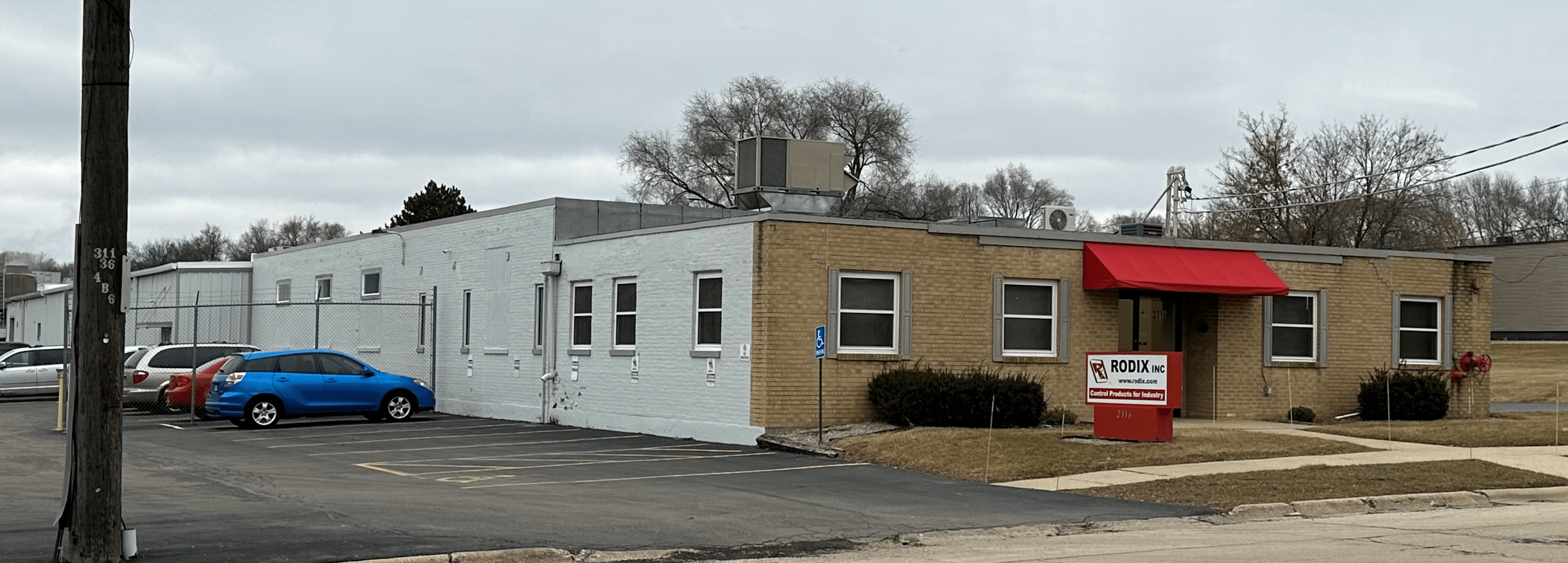

Rodix, Inc.

May 5, 2021Founded as a Wholly Owned Subsidiary in 1971.

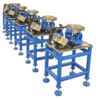

Rodix, Inc. is located at 2316 23rd Ave. Rockford, IL. Since its inception Rodix has been providing the parts feeding industry with vibratory feeder controls and basic unmachined feeder drives designed and built to the highest standards of quality. The Rodix staff takes immense pride in their ability to meet the growing on-time delivery expectations of its diverse customer base. Our success is directly attributed to the relationships we have with Our customers. As well as a straightforward design, use of high-quality components, and the staff’s ongoing commitment to quality and customer service. Our staff understands the need for long-term product support and on-demand technical assistance required to keep the customer’s product flowing around the clock. Rodix products can be found across the globe in machinery serving industries such as fasteners, pharmaceutical, automotive, medical, munitions, electrical component, and food packaging and assembly.

May 5, 2021

Rodix vibratory feeder controls are broken down in two product categories: Fixed Frequency (FC Series Controls) and Variable Frequency (VF Series Controls). Fixed Frequency controls offer a pulsed output to the feeder based on the AC line frequency. Variable Frequency controls use frequency inversion allowing the control’s output to tune to the natural resonant frequency of the feeder. All Rodix controls are available with either analog or digital interfaces, while standard packaging options include Open Frame, General Purpose (Nema 1), and Oil Resistant (Nema 12). Rodix controls are ready to work with optical sensors (PNP/NPN), proximity sensors, PCLs, air jet assist manifolds, as well as Rodix designed feedback sensors allowing for both automatic frequency tuning and continual amplitude adjustments of the feeder. Rodix is also able to meet unique customer application requirements by quickly adapting our standard product lines into special installations and enclosures. Rodix’s standard products are UL/cUL listed, with CE options available within each product family. All Rodix products are assembled, tested, and shipped from our location in Rockford, IL. Rodix is certified ISO9001:2015 with Design.

Click Images to Enlarge

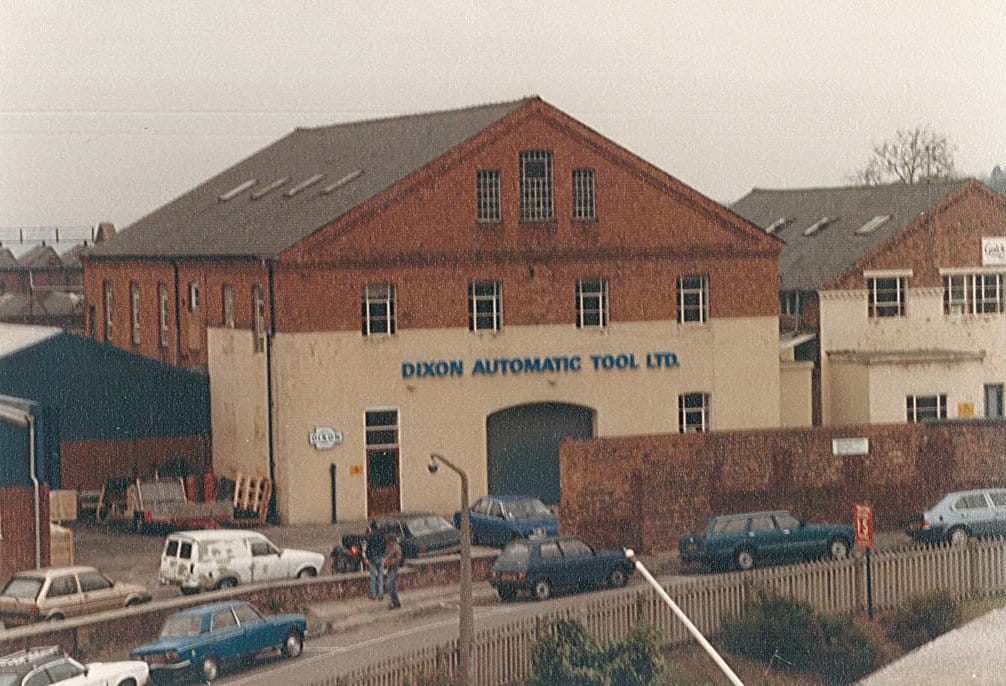

Dixon Automatic Tool, Ltd. England

May 5, 2021

Our Company started a manufacturing operation in England in 1977. The new manufacturing facility in England would expand the sales of assembly machines into the UK market, and also to the European market. Our new Company was incorporated as Dixon Automatic Tool, Ltd. in the city of Worcester, which is centrally located for our operation. We leased a suitable building, and hired talented personnel to begin the first year of operation. During the following years, our assembly machines were sold to many of the major manufacturers in England and Wales. Our managing Director and staff was exceptional, and are responsible for the outstanding work accomplished during the 18 years of our operations in England. We closed due to a long, extended downturn in the economy, and high goverment mandates.

Click Images to Enlarge

Dixon Automatic Tool, Inc. Canada

May 7, 2021

Dixon purchased a division owned by Arbell Equipment Co. located in Stoney Creek, Ontario, Canada in 1981. Their divison fabricated Vibratory parts feeders. At the signing of the articles of incorporation, the new company’s name was given Dixon Automatic Tool, Inc. The major priority of the new Company was to increase sales of tooled vibratory feeders, and related feed systems. Each year the Company also produced a small percentage of custom built assembly machines. Any requirements for automatic part placements or screwdriving stations were purchased from the Rockford facility. The Company was later renamed Dixon Automation, Inc. After 14 years of successful operation in Canada, our corporate officers in Rockford arranged the sale of the Canadian facility to their managing Director, Mr. Gerald McKnight.

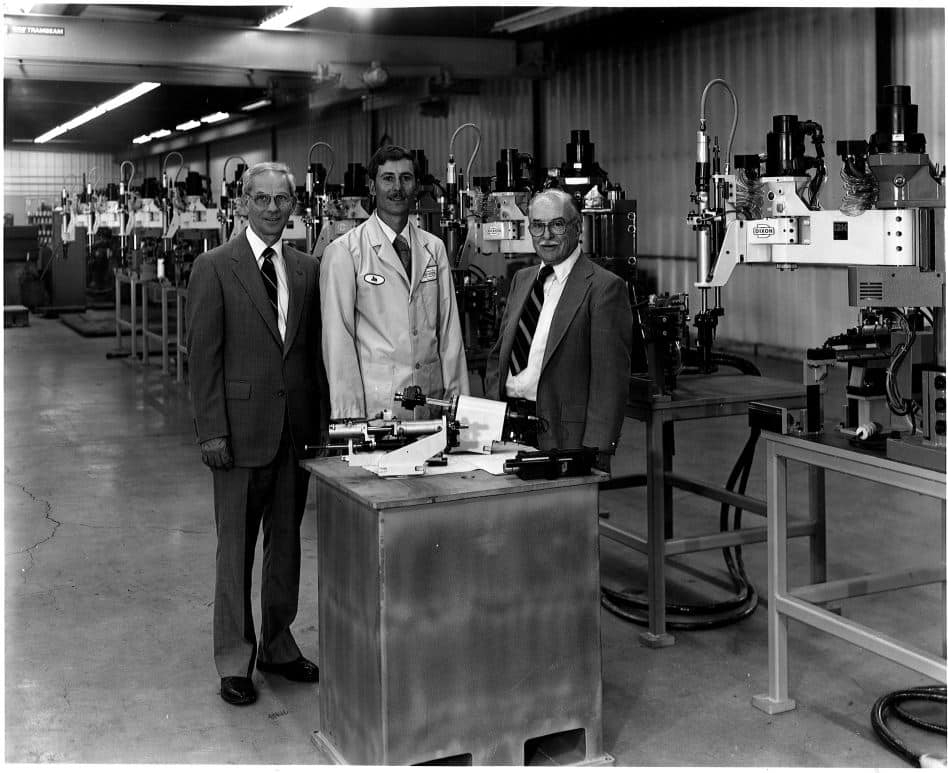

In 1983 we increased the size of our Manufacturing dept.

May 7, 2021

With growing orders, the Company increased the size of our second Facility at 2303 23rd Avenue by adding 17,500 square feet of work space. This solved the need to house additional machine tools used to fabricate component parts, and also provided space for the assembly and testing of machines and work stations. IBM Robots were used for our first automated work stations for programmed positioning of our Auto-Fed Screwdrivers or part placers.

Left to Right

John H. Dixon, James C. Dixon, Paul H. Dixon

Design Enhancements

Dixon Automatic Tool, Inc. expended into Robotic Assembly Solutions enhancing our design capabilities.

Click Images to Enlarge

Dixon Automatic Tool, Inc. partnered with Stöger Automation GmbH

May 8, 2021

In the summer of 1994, we sent our sales manager and one of our engineers to the Motek Automation Show in Sinsheim Germany. While at the show, we were very fortunate to meet Mr. Lorenze Stöger, owner of Stöger Automation GmbH at his display booth. We expressed our interest in marketing the Stöger products here in North America. For the next 14 months, the Stöger team and the Dixon’s had many visits both at the Rockford plant and at the Stöger plant in Germany. In Nov. 1995, we both signed a contract to represent Stöger’s Products in North America.

Click Images to Enlarge

LS/LSR

May 9, 2021Presenting the LS/LSR Screwdriver Series

|

The Dixon team was featured in the July 2020 edition of Assembly Magazine.

May 27, 2021We were pleased to offer our expertise on the installation of nonthreaded fasteners.

Our products are the result of years of design and development work involving parts handling for automated assembly. Our staff has always been focused on engineering and creating new products aimed to improve productivity. The proven reliability of Dixon products and their rugged durability makes Dixon the No. 1 choice of many major manufacturers and machine builders.

August 25, 2022

A Recognized Leader in Automated Assembly Products and Services