AP-100 Series Part Placing Head

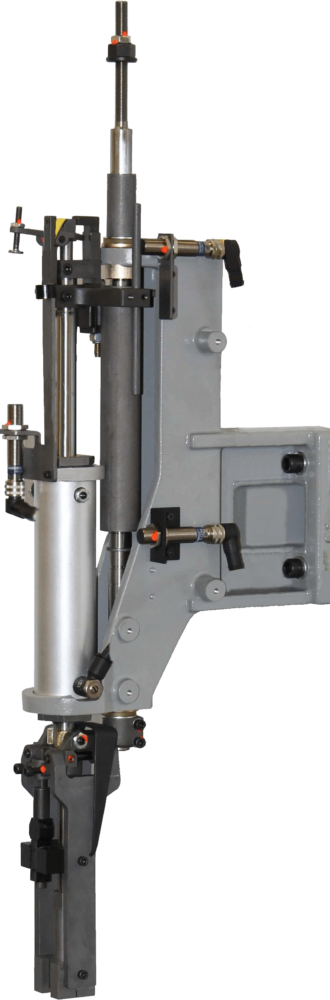

AP-100 Series Part Placing Head – Part Placers are used for various applications and the type of feeding system required is determined by the part geometry and placement of the part. AP-100 head is capable of placement rates of up to 80 per minute which sets it apart from other basic pick and place units. The AP-100 head has a placing cylinder that is cushioned at both ends, with strokes from 2-5 ins. and pressing forces between 40 and 175 pounds. The hardened jaws are custom machined to grip and align each piecepart and then mechanically opened by a cam assembly as the piecepart engages the workpiece. Each piecepart is properly placed into the workpiece using verification sensing. Control switches also provide for the driving head to return and other auxiliary functions as may be required.

| Standard 100 Series Part Placing Head Components | |

| Head Stroke | 50.8 mm, 76.2 mm, 101.6 mm, 127 mm (2 in., 3 in., 4 in., 5 in.) |

| Pressing Force | 177-778N (40-175 lbs.) Standard Max 378N (85 lbs. Force) 38.1mm (1.5 in.) Cylinder Optional Max 778N (175 lbs. Force) 50.8mm (2.0 in.) Cylinder |

| Air Supply | 6.3 Bar (90 PSI) |

| Proximity Switch | Std: 24 VDC PNP Others Optional |

| Valves | 24 VDC Low Watt Coils Standard Others Optional |

| Inline Load Cells Can Be Added | |

100 Series Part Placer Head Feed System:

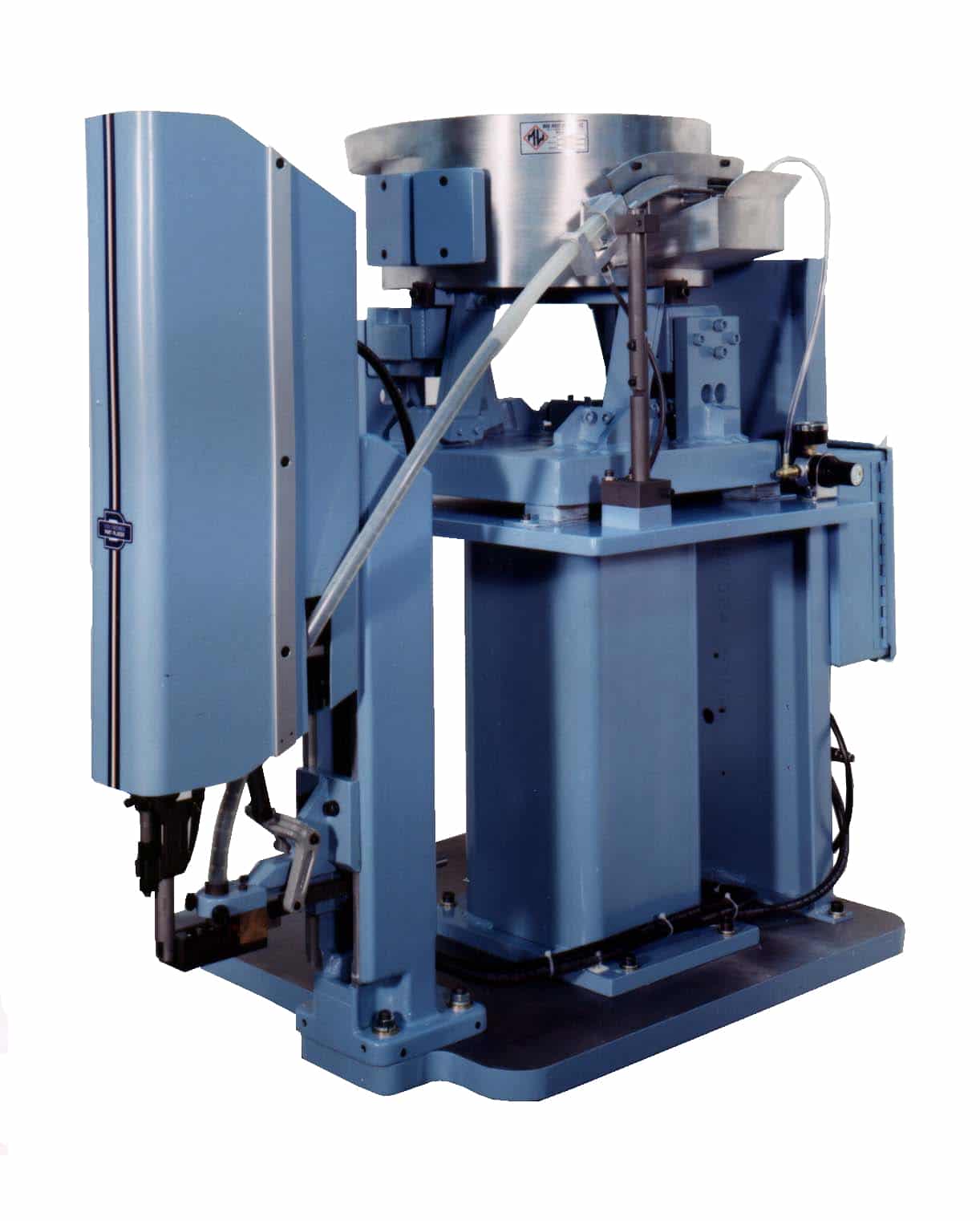

- Model AP-107 Part Placer with Rotary Hopper

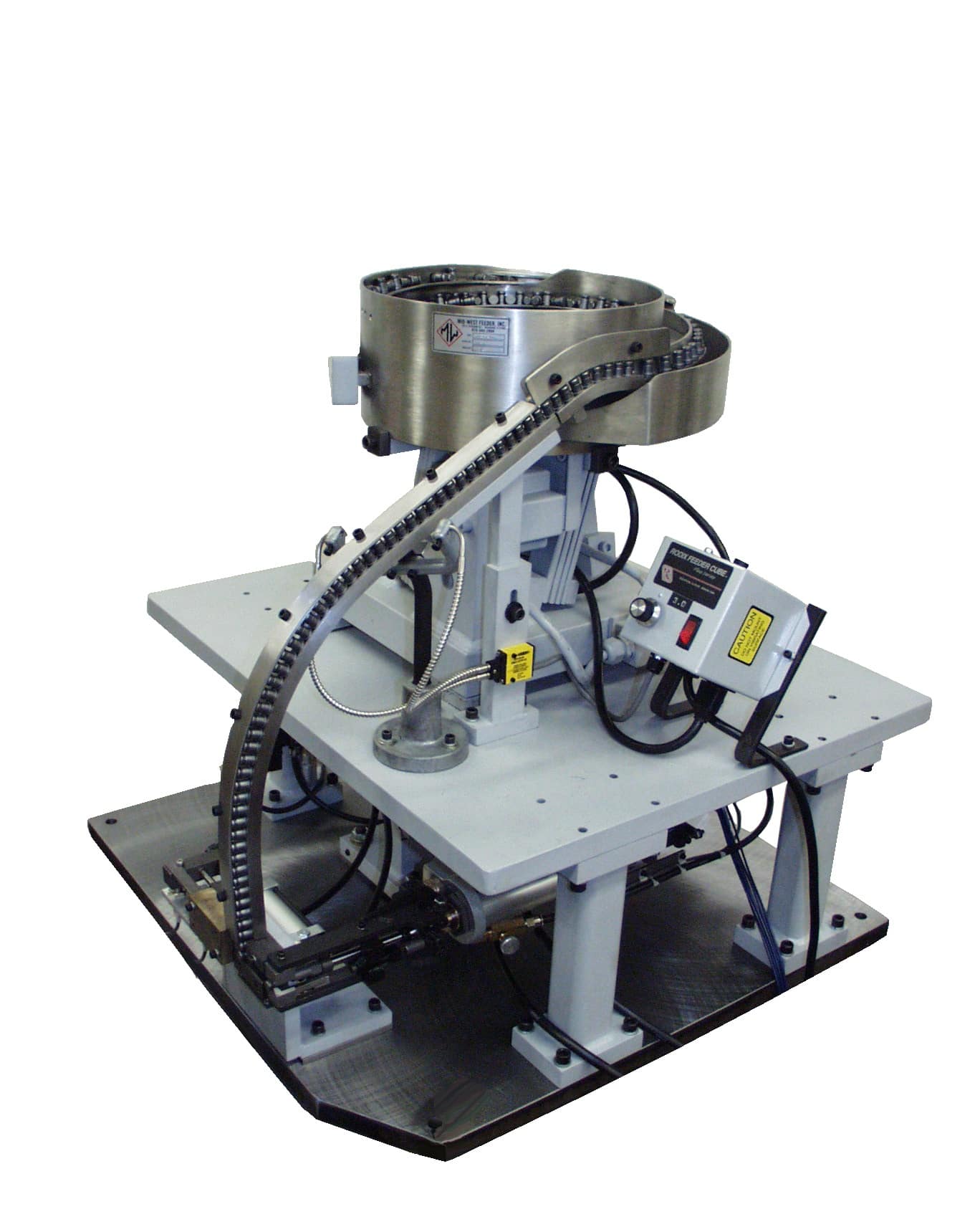

- Model AP-110 Part Placer With Track And Vibratory Feeder Bowl

- Model AP-111 Part Placer With Vibratory Feeder Bowl And Horizontal Track

- Model AP-120 Part Placer With Drop Tube And Vibratory Feeder Bowl

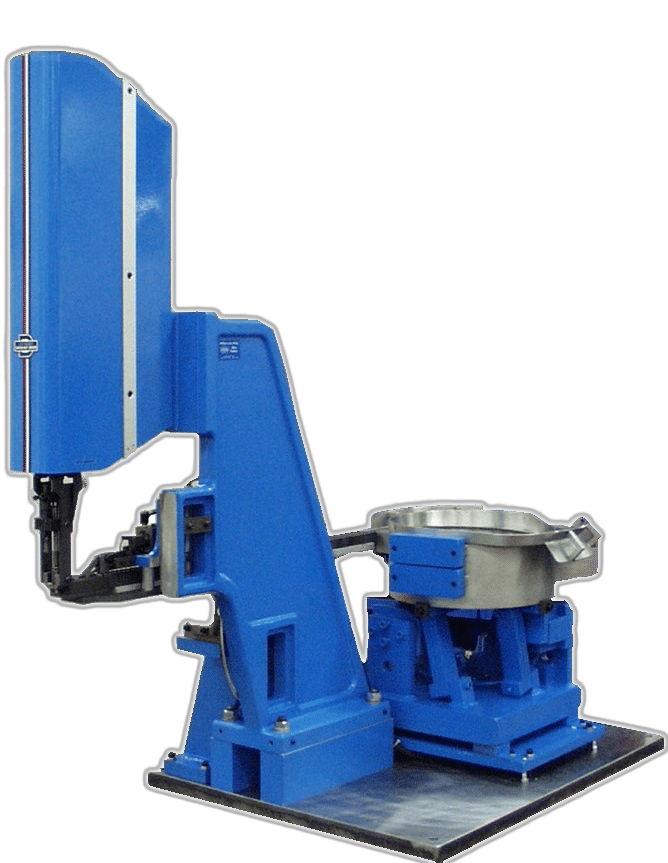

- Model AP-122 Horizontal Part Placer with Vibratory Feeder Bowl

- Model AP-127 Part Placer With Extended Throat And Vibratory Feeder Bowl

- Model AP-171 Robotic Placer With Trav-a-Track