When your automated production requirements include efficient and precise fastening of screws, an auto-fed automatic screwdriver can be a game-changer. It’s designed to automatically feed screws from a storage or supply system and drive them into a product without the need for manual handling, making it an especially valuable assembly automation tool in industries such as electronics, automotive, aerospace, and more.

The heart of the system is a screw feeding mechanism that supplies screws to the driver unit, which is responsible for picking up individual screws and driving them into the product.

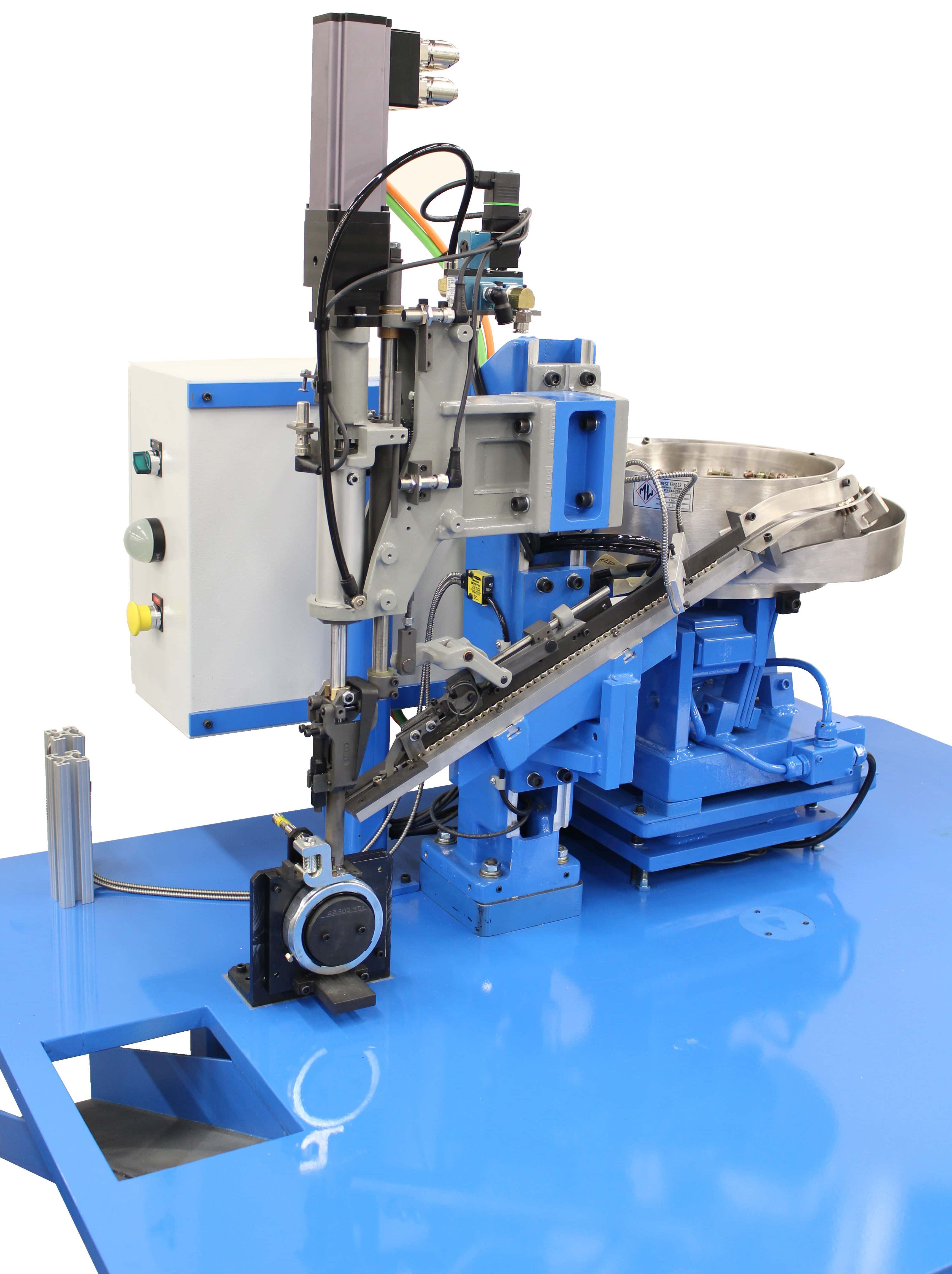

The auto-fed automatic screwdriver (Model SD-116) is fully automatic and equipped with a vibratory feeder bowl with vibration controls, hardened inclined steel track mounted alongside the support column for easy access, and a transfer escapement that positions each fastener into the placement jaws of the screwdriving head. The placement jaws hold the fastener’s threads in position until the fastener is engaged in the workpiece. The screwdriver head has built-in sensing to confirm proper insertion of each fastener into the workpiece. The baseplate size is determined by the size of the feeder bowl system.

The Model SD-116 Screwdriver is ideally suited for automated screwdriving applications. The driver can be tooled for a broad range of fasteners. The feeder bowl and track can also be tooled for dimensional variances with your fasteners when specified with your order. Primary benefits include improved production efficiency, reduced labor costs, increased accuracy, and enhanced product quality. By automating the screw fastening process, manufacturers can achieve higher throughput, reduce the risk of human error, and maintain tight quality control standards.

In this video we used a servo motor to turn the drive shaft and drive the screws. Note, two drivers are to a depth and the last is driven to a torque to hold the lug.