|

Automatic screwdrivers simplify the task of driving screws into various materials or products. They are designed to increase efficiency and accuracy in assembly and manufacturing processes that involve a high volume of screw fastening applications. Industries such as automotive, electronics, aerospace, and consumer goods manufacturing typically incorporate automatic screwdrivers into their work units.

Benefits include:

- High-Speed Assembly. Automatic screwdrivers are designed to work at high speeds, making them ideal for assembly lines that require rapid and continuous screw fastening. This increased speed can significantly boost production efficiency.

- Consistent Screw Tightening. These machines ensure that each screw is tightened to the same torque and depth specifications. This consistency is essential in industries where product reliability and safety are paramount.

- Reduced Labor Costs. By automating screwdriving tasks, manufacturers can reduce the need for manual labor in assembly processes. This leads to cost savings and allows workers to focus on more complex and value-added tasks.

- Improved Ergonomics. Assembly automation reduces the physical strain on workers by eliminating repetitive and physically demanding screwdriving tasks. This can lead to a safer and more comfortable working environment.

- Versatility. Automatic screwdrivers can handle a wide range of screw sizes, types, and materials. Tooling changes are typically straightforward, making it easy to adapt to different assembly requirements.

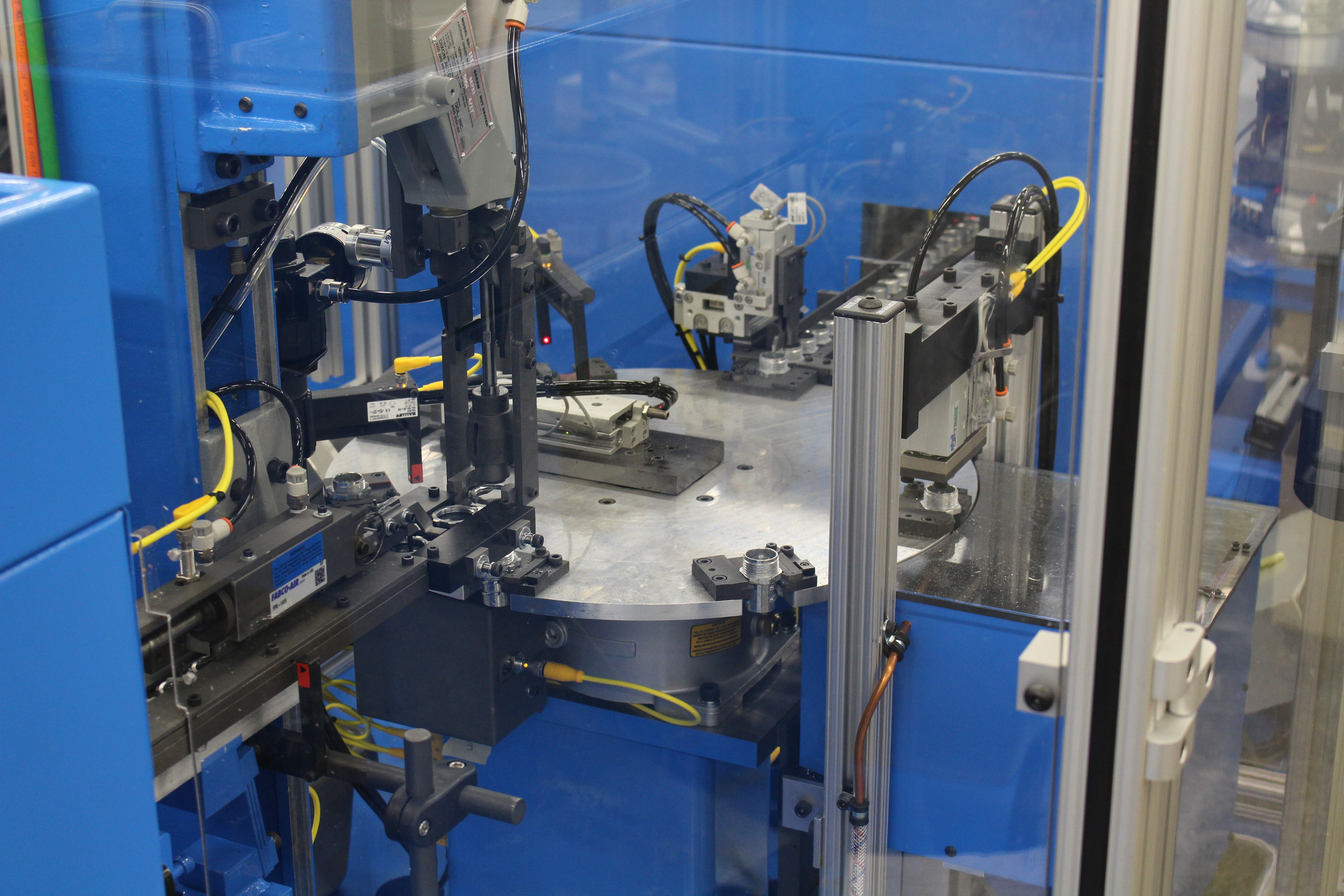

The auto-fed automatic Screw/ Nut driver (Model SD-111) is fully automatic and equipped with a vibratory bowl feeder, horizontal hardened vibratory feed track, support column, and a transfer escapement that positions each fastener into the placement jaws of the screw/nut driving head. The placement jaws hold the fastener in position until the fastener is engaged in the workpiece. The screw/nut driving head has built-in sensing to confirm proper insertion of each fastener into the workpiece. The baseplate size is determined by the size of the feeder bowl system.

The Model SD-111 Screw/Nut Driver is designed for a broad range of parts, screws, and nuts, including fasteners with extremely short body lengths, captive washers, or wire clamps.

In this video we are driving an electrical fitting nut.