Reconditioning and Updating Screwdriver from 1987

Our customer contacted us about reconditioning one of our Screwdrivers that we had built in 1987 for them. The customer will be using this Screwdriver in a different configuration and needed new tooling. We had the customer send us the Serial number of the screwdriver. This enabled us to review how the original unit was manufactured. We also re The customer sent in the unit to us, which allowed us to provide them with an accurate quote. The customer also requested that the unit be converted from an SD-107 drum feeder, into an SD-110 style minus the feeder bowl. The customer would be adding the feeder bowl on at their location.

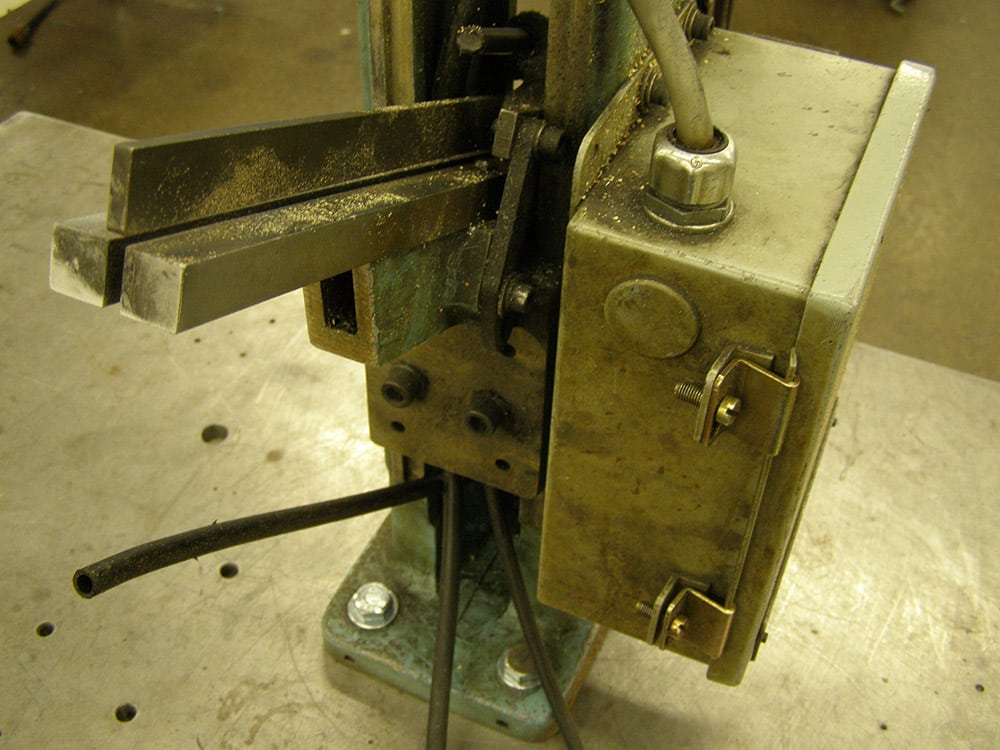

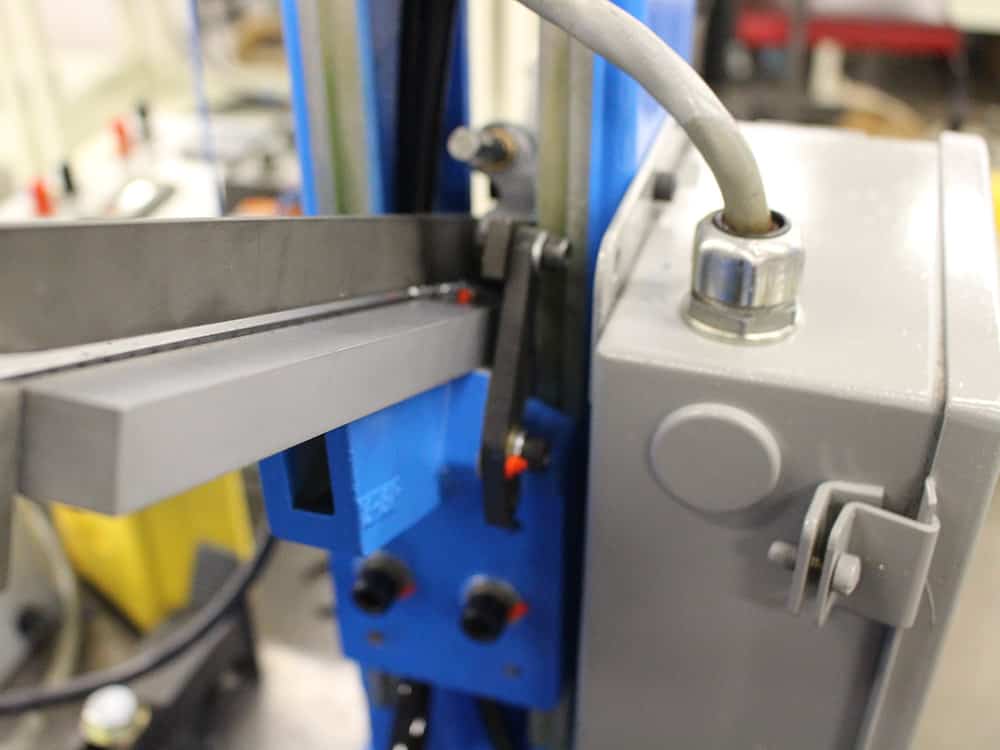

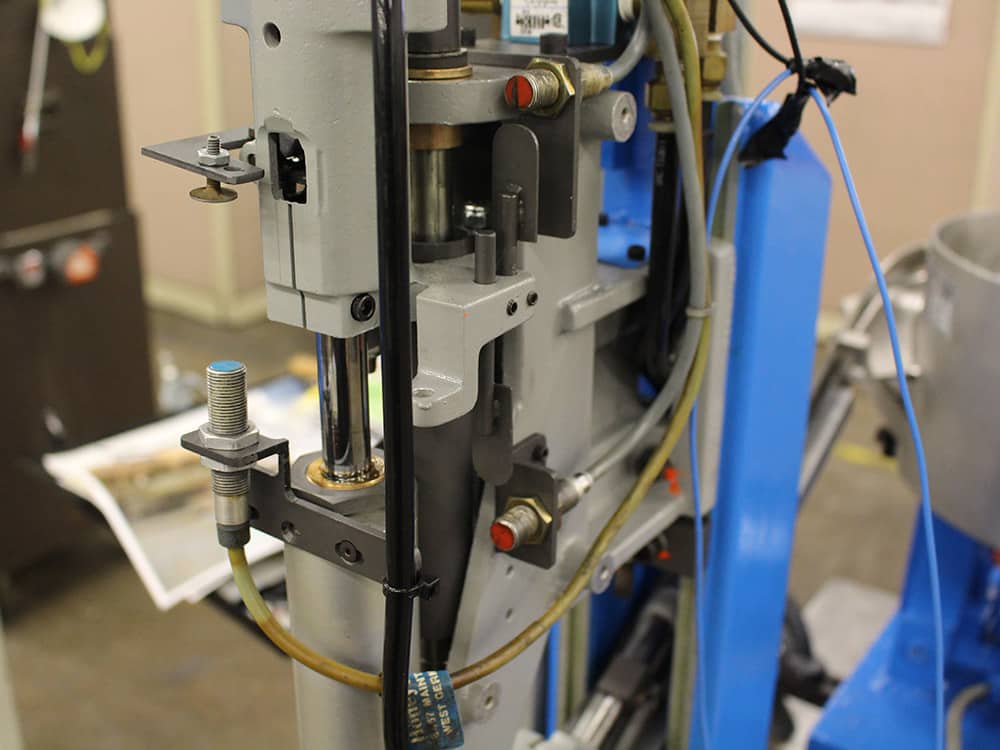

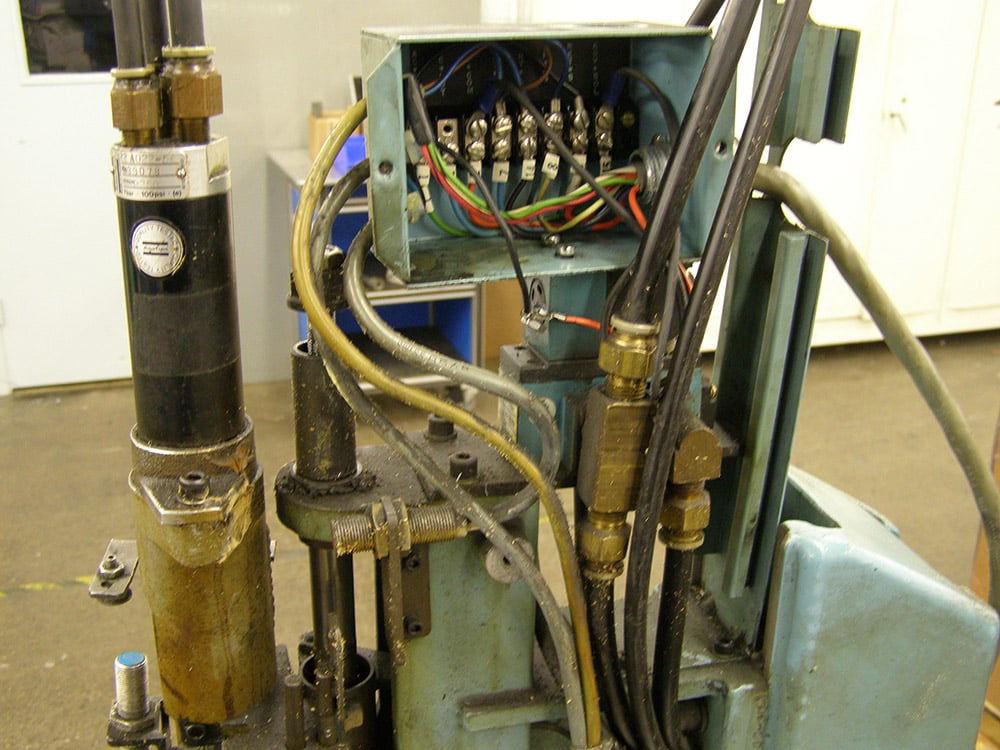

Scroll images to see the before and after.

Quoting

We reviewed the original unit that was purchased. With that information and the Customers new specifications and were able to generate a proposal for them.

Refinishing

All items were cleaned, parts needing repainting are sandblasted and painted with Dixon Blue.

Rebuilding

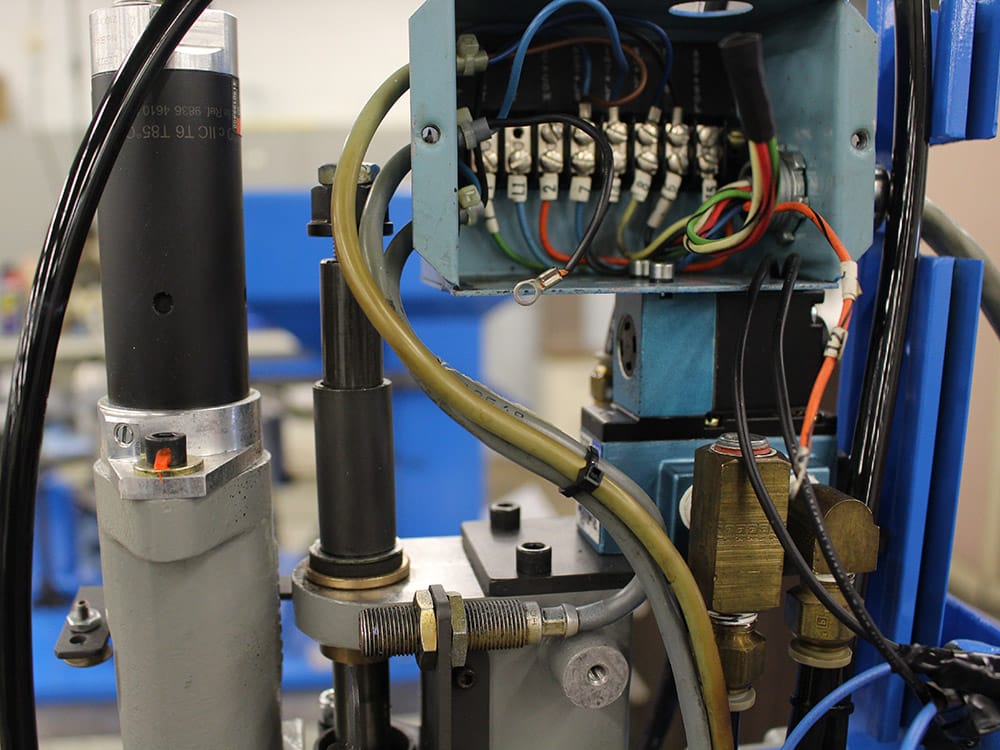

This rebuild required the following new items air motor, solenoid control valve, air lines and all related feed track parts and tooling. During the reconditioning process replaced all seals in the driver cylinder, and replaced all bearings in the head and escapement assembly. We also updated the Screwdriver to use 120V single solenoid control valve over the older model MC-9 valve. The feeder bowl was sent out to be retuned for the updated screw specifications. The rebuild process happens like any new screwdriver, the unit is assembled according to the Customer specifications. The screwdriver was rebuilt to include new advances that we had added to our current product lines. Each screwdriver is set to the Customers new requirements in drive height, torque or depth. A new manual was sent to the Customer.