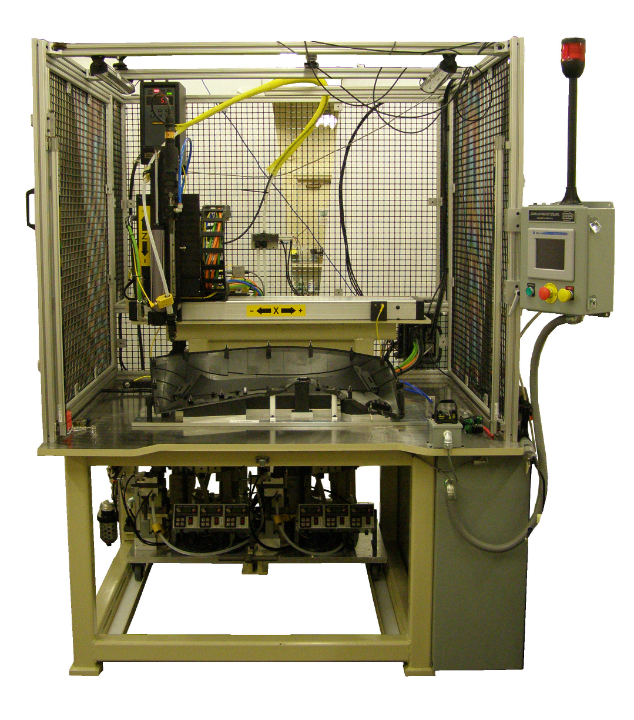

3400 Work-Cell

The Model 3400 Work-Cell is an ideal workstation for semi-automated assembly operations requiring automated fastening or part placement. An operator manually loads and clamps the workpiece assembly into a dedicated work-holding fixture and initiates the cycle. One or more assembly heads can be mounted on a Cartesian slide to move forward/back and left/right over the fixture, making the cell well-suited for applications requiring “random” fastener/component placement across a range of workpieces. The standard placement work area is approximately 305 mm x 305 mm, and the cell’s flexible design supports easy retooling and reprogramming for future product changes.

To match the application, the 3400 can be configured with Dixon’s standard auto-fed screwdriving heads (selected based on fastener size and torque requirements) or converted for part placement by replacing the screwdriver head with a Part Placement Head (selected based on pressing force requirements). Optional placer head configurations can support a range of stroke lengths and pressing forces, with placement depth precision dependent on the fastener/component.

Fasteners or components are automatically presented using an appropriate feed system, with vibratory feeder bowl sized for the cycle rate and part being fed (with feeder bowls available up to 533 mm). Because the operator is manually loading and unloading assemblies, the cell is typically equipped with a complete guarding package—commonly including light curtains, mesh panels, and an aluminum extrusion structure—supporting efficient operation while maintaining appropriate safeguarding. Controls can include a user-friendly touchscreen interface, easy programmability, and standard error messaging to support day-to-day production use.

Products Page![]() Request a Quote

Request a Quote