General Manufacturing & Assembly

Manufacturers across industrial, commercial, and OEM markets rely on Dixon Automatic Tool, Inc. for fast, reliable, and flexible assembly automation. From fastener driving and part placement to vibratory feed systems and robotic work cells, our tools help streamline production, reduce manual handling, and improve quality across a wide range of products and assemblies.

Systems That Fit the Work

Our equipment handles anything from small electronics to large structural assemblies, and every system is adjusted to match the pace and demands of the plant floor.

Automatic screwdrivers

Auto-fed screwdriving systems that deliver fast, consistent fastening for a wide range of general manufacturing assemblies. Easily integrated into fixtures, presses, indexing tables, and small special machines built by OEMs and integrators.

- Versatile screwdriving for many product types

- Consistent torque and depth control

- Scales from pilot lines to high-volume production

Nut runners

Automatic nut drivers that apply precise torque to studs, bolts, and nuts in industrial and commercial product assemblies.

- Supports both low- and mid-torque ranges

- Fits into compact assembly stations

- Good fit for contract manufacturers and machine builders

Part placers

Position and install piece-parts using track-fed or blow-fed delivery for precise placement.

- Helps reduce repetitive motion and alignment errors

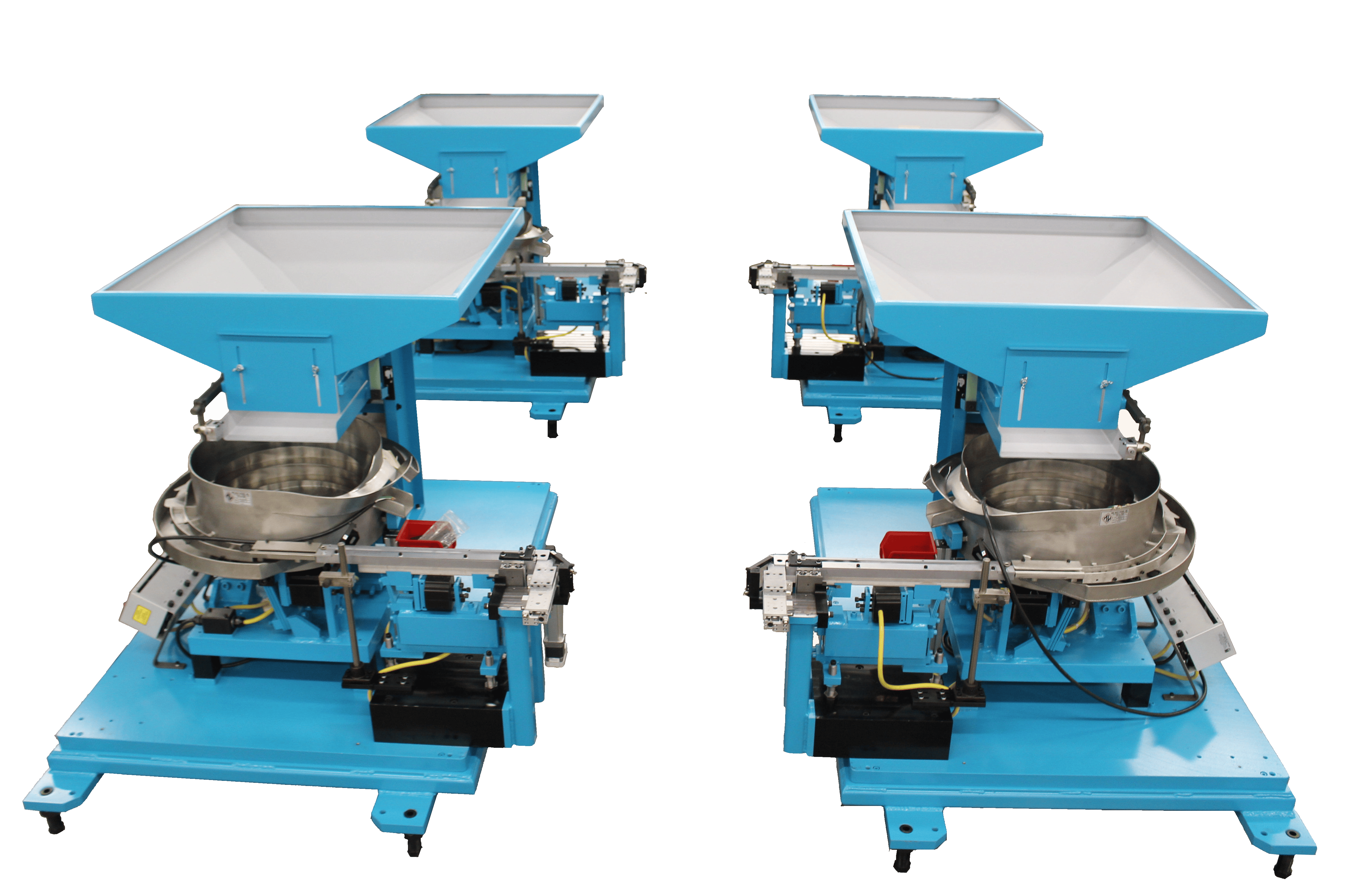

Feed systems

Bowls, hoppers, and tracks – keep hardware flowing with the line, always ready for the next cycle.

- Provides reliable flow to assembly products.

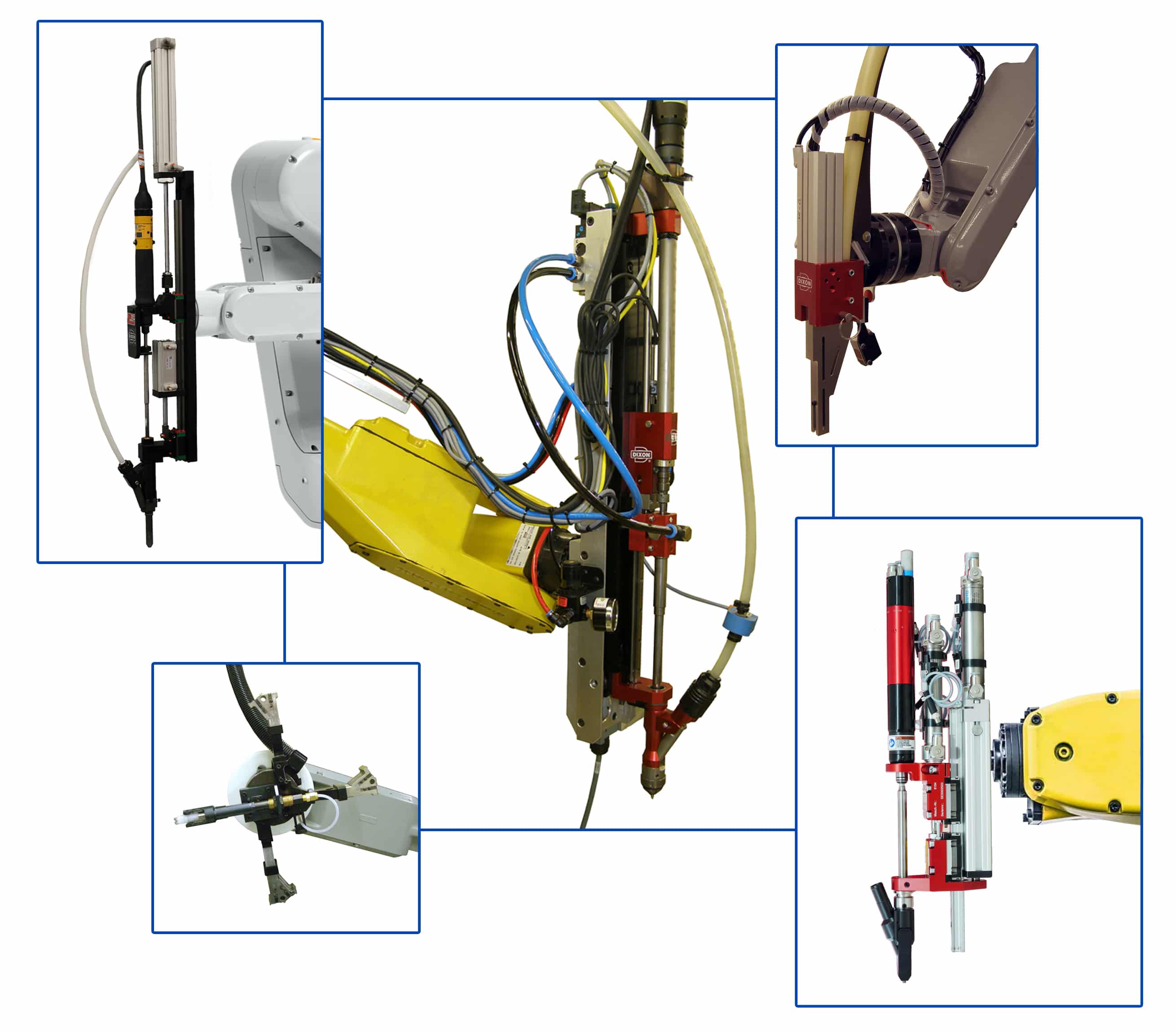

Robotic end effectors

Bring all of it into automated cells, fastening and placing with the same accuracy of the manual stations.

Where It’s In Use Across Production

You’ll find Dixon systems embedded in the assembly of consumer and commercial products, in mechanical and electrical sub-assemblies, in panel, housing and frame fastening, and even in end-of-line or packaging stations.

Reliable in Every Shift

Consistency matters more than raw speed when production runs long and the parts vary. Dixon systems hold torque, maintain alignment, and feed reliably through hours of use, multiple operators and shifting conditions.

Get in touch with our team about a fastening or feeding setup suited to your assembly process.

Industries Served by Dixon Automatic Tool

Automotive & Transportation

Powertrain and interior assemblies demand absolute precision. Dixon Automatic Tool solves this by engineering equipment that integrates total control into the process, ensuring every fastener hits its mark in high-volume production.

Electronics & Consumer Goods

Balancing high-volume output with precision quality is a constant challenge for electronics manufacturers, especially when dealing with delicate components and the relentless pace of modern product innovation.

Appliances & Building Products

To stay competitive, appliance and building-product manufacturers must master the complex assembly of metal and plastic components across a vast product range—from domestic white goods to mission-critical construction and safety hardware.