Efficiency and dependability are the driving factors behind successful manufacturing operations, and feed systems contribute greatly to maintaining these qualities throughout. Dixon Automatic Tool, Inc. specializes in supplying reliable and high-performing feed systems, from vibratory feeder bowls to supply hoppers and custom feed tracks. These systems are trusted by many to deliver the precision and consistency needed in manufacturing production lines, ultimately resulting in higher productivity levels and less downtime.

Understanding Feed Systems

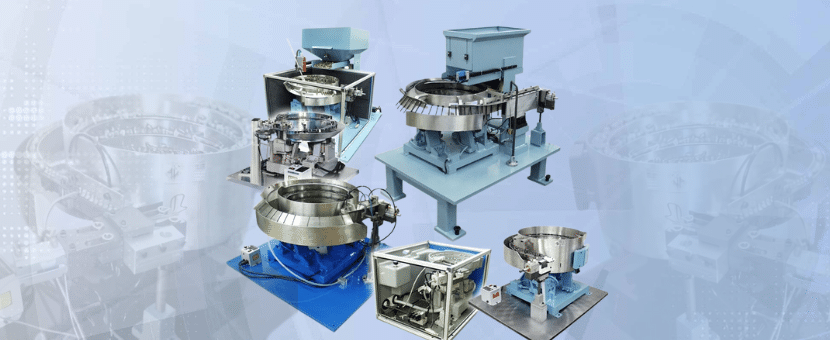

Feed systems automate the sorting, orienting, and delivering of various parts or fasteners, which keeps assembly lines running smoothly. Whether it’s vibratory feeder bowls, inline tracks, or supply hoppers, each component is integral to the efficiency and accuracy of these operations.

Our vibratory feeder bowls are available in stainless steel or cascade options, and they come in a wide range of diameters to best suit your parts. These bowls are tooled to handle various pieceparts or fasteners for a simple integration with your production line. For additional support, we also offer supply hoppers with capacities of up to 5 cubic feet. These hoppers maintain an optimal part level in the feeder bowls for maximum efficiency.

Each feed system includes additional components such as inline vibratory track drives or gravity incline tracks. Equipped with drive controls, our systems can be fully customized to meet unique manufacturing requirements. We also integrate sound enclosures to reduce noise levels and incorporate custom feed tracks to ensure precise part orientation and accurate delivery.

Why Choose Dixon’s Feed Systems?

Selecting the right feed system is imperative to the success of your operations, and it’s important to weigh considerations like efficiency, longevity in performance, and the ability to be customized. Dixon Automatic Tool’s feed systems offer all of this and more. This is what sets our feed systems apart:

- Customizability: From part orientation to delivery, our systems can be tailored to meet the goals of your specific operation.

- Durability: Our feeder systems are made with top-level materials like stainless steel to ensure reliability in the long-haul.

- Efficiency: Features like supply hoppers and advanced feeder controls maintain consistent part flow and reduce downtime.

Additional Features

In addition to the core features of our vibratory feeder bowls, we have several optional components to further enhance the performance and overall experience of your system. Here’s a look at some of the options available:

- Feed Tracks: Our tracks are designed to guide parts from the feeder bowl to their delivery point, and they can be customized for horizontal or inclined applications.

- Supply Hoppers: These maintain a smooth and consistent flow of parts to the feeder bowl, which limits the need for manual intervention.

- Sound Enclosures: Fabricated from 18-gauge steel, we offer sound enclosures lined with sound-absorbing material to reduce noise and create a more comfortable work environment.

Applications Across Industries

Dixon feed systems are trusted for their dependability and performance across numerous industries, including automotive, electronics, pharmaceuticals, and more. In the case that you’re assembling fasteners, processing small parts, or handling delicate components, our solutions are fully customizable and can match the exact demands of your operation.

Trust Dixon’s Solutions to Automate Your Production

The team at Dixon Automatic Tool, Inc. serves a commitment to helping manufacturers streamline their production lines with the most efficient and reliable feed systems on the market. Browse our full range of feed systems here and see how they can transform the success of your assembly processes. If you’re seeking a custom solution, get in touch with our team today to request a quote, and our experts will work with you to find the right system for your operation.