Appliances & Building Products

Appliance and building-product manufacturers assemble a huge range of sheet-metal, plastic, and cast components—from washers, dryers, and refrigerators to electrical box builds, plumbing and fire protection devices, and construction hardware. Dixon Automatic Tool provides automatic screwdrivers, nut runners, part placers, feed systems, and robotic end effectors that help automate fastening and small-part handling on these products while maintaining durable, field-ready quality.

For Demanding Assembly Work

From compact drives and actuators to large enclosures and subframes, our systems handle the vast range of parts found in industrial and appliance manufacturing applications.

Automatic screwdrivers

Keep fasteners seated cleanly at production speed using controlled torque and depth for consistent engagement.

- Handles a range of sheet-metal and self-tapping screws into steel, aluminum, and coated panels used in appliances, construction products, and electrical box builds.

- Can be integrated into bench fixtures, inline stations, or small workcells, giving OEMs and integrators a drop-in way to automate repetitive screwdriving operations.

Nut runners

Drive threaded joints that have to hold under load, for long cycles and tight tolerances.

- Available in inline, angle, and horizontal configurations and easily paired with feeders so hardware is automatically presented to the driver instead of hand-started from bins.

Part placers

Pick-and-place stations for piece-parts and components delivered with feeders that orient and dispatch parts precisely.

- Fits easily into rotary dials, transfer lines, and lean assembly cells, making it a standard building block for repetitive insertion on cabinets, frames, and building hardware.

- Automates placement of wire and tube grommets, insulation clips, plastic anchors, escutcheons, spacers, bushings, and brackets used in appliances, electrical boxes, plumbing and fire devices, and door/window assemblies.

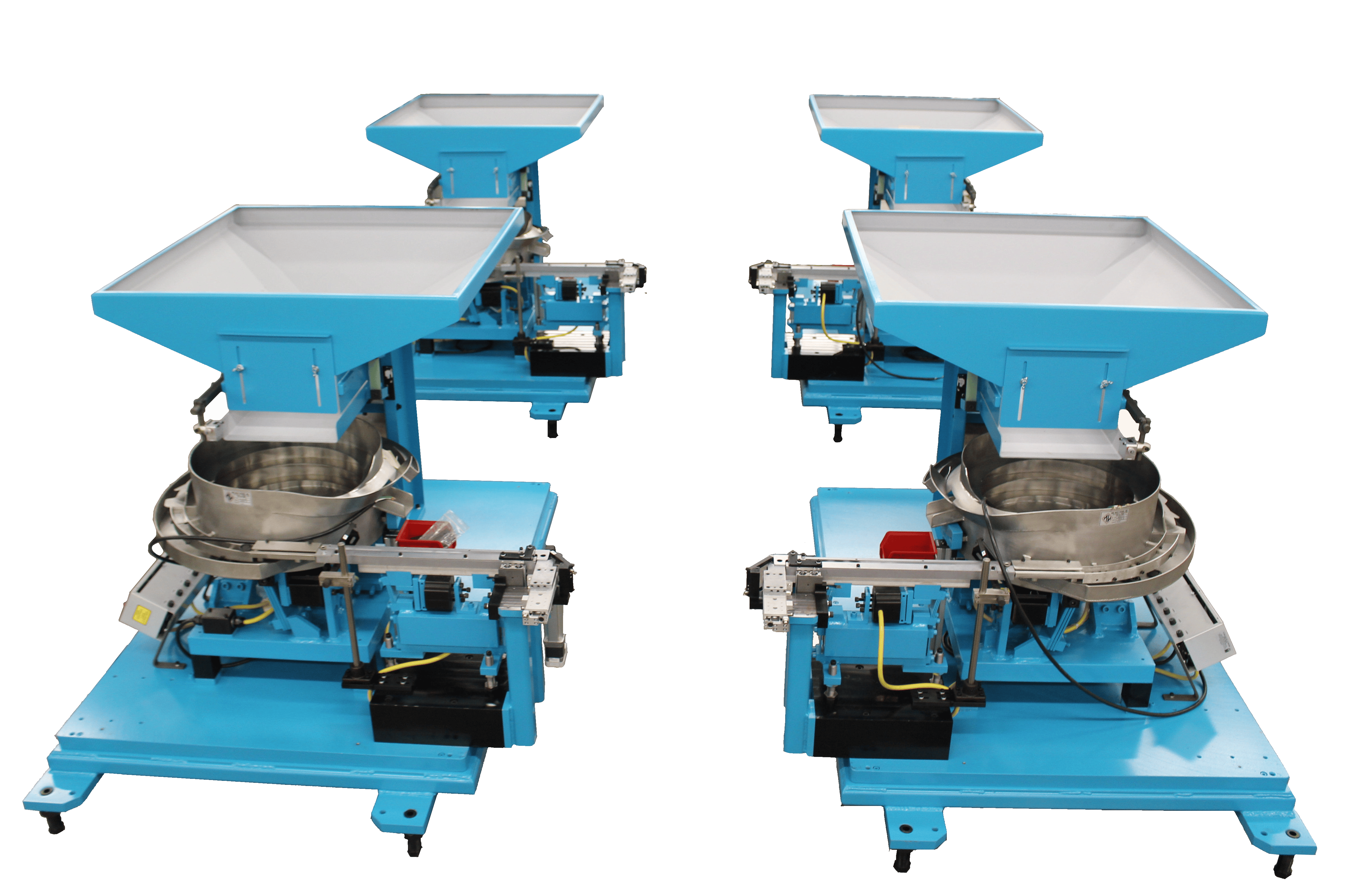

Feed systems

Bowls, hoppers, and tracks keep parts moving with the line, feeding each station at the rate it works.

Supply hoppers, level sensing, and drive controls maintain steady flow and help lines run longer between operator interventions—important on large appliance and construction-product lines.

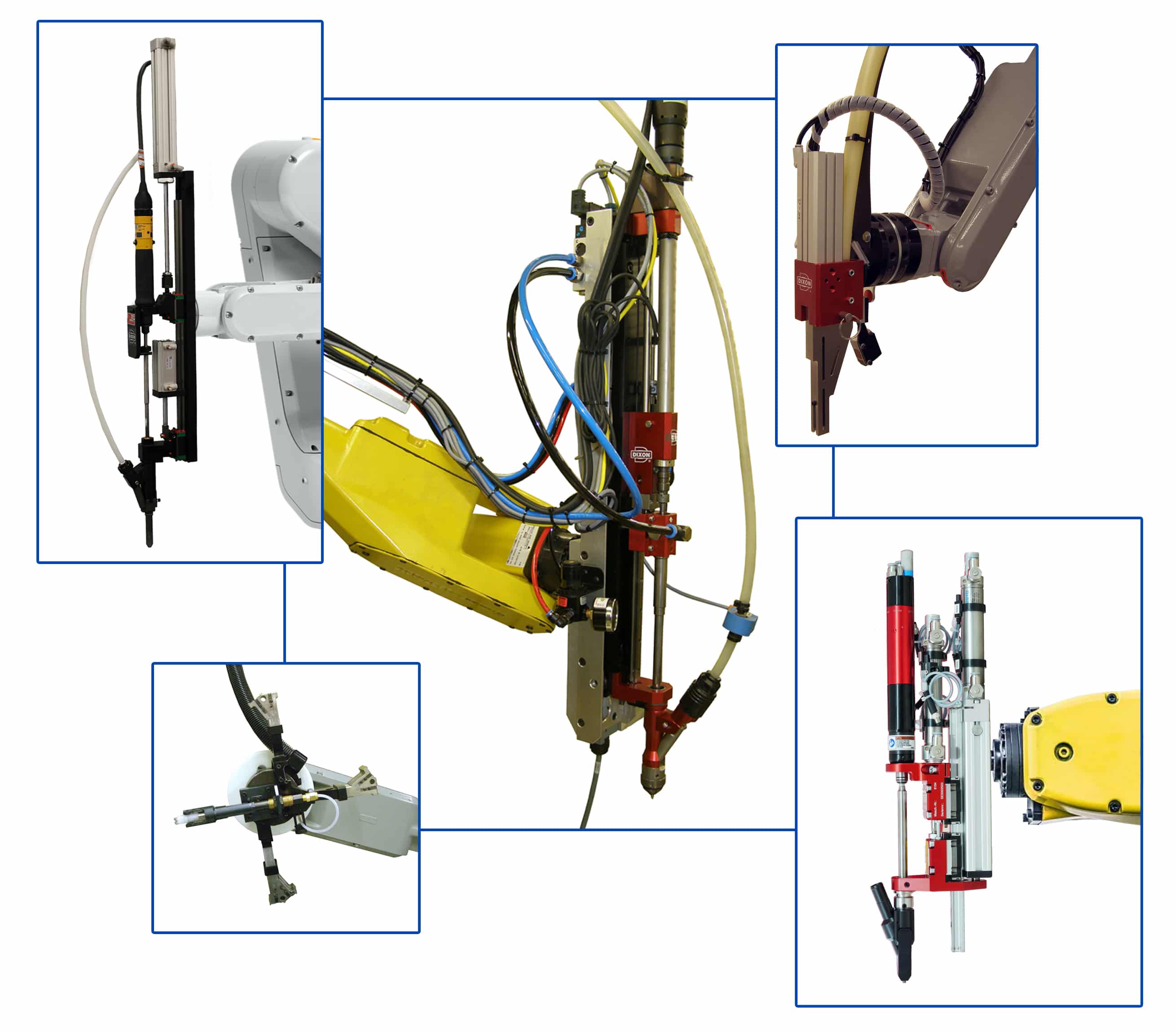

Robotic end effectors

Bring those same functions into automated cells, handling fastening and placement on robot arms with vision or verification when required.

- Can be delivered as tooled robotic stations or integrator-ready heads, and often paired with sensing or vision to find holes and features on painted, formed, or extruded building components.

- End-of-arm tooling can pick fasteners or small parts from feeders, position them on cabinets, doors, frames, or panels, and complete screwdriving or pressing in one robotic move.

Where Our Equipment Is Used

Dixon systems support the assembly of pumps, valves and compressors, the manufacture of control panels and housings, structural fastening in appliance frames, and the sub-assembly of mechanical and electrical units. These systems integrate very well into multi-stage operations where one station hands off to the next, and every fastener must hold its place once production moves on.

Consistent Output, Shift After Shift

Industrial lines cannot afford hesitation. Dixon systems hold their mark through hours of heat, noise, and motion, holding the line’s pace and the work’s integrity. Drives keep their torque, feed tracks stay in time, and the assemblies keep landing right where they should.

Contact our engineers about a system configuration that matches your machinery or appliance requirements.

Industries Served by Dixon Automatic Tool

Automotive & Transportation

Powertrain and interior assemblies demand absolute precision. Dixon Automatic Tool solves this by engineering equipment that integrates total control into the process, ensuring every fastener hits its mark in high-volume production.

Electronics & Consumer Goods

Balancing high-volume output with precision quality is a constant challenge for electronics manufacturers, especially when dealing with delicate components and the relentless pace of modern product innovation.

General Manufacturing & Assembly

Our integrated solutions—from precision fastener driving to fully automated robotic work cells—eliminate these inefficiencies, streamlining your production and ensuring superior quality across even the most complex assemblies.